What is Welded Wire Mesh

Overview

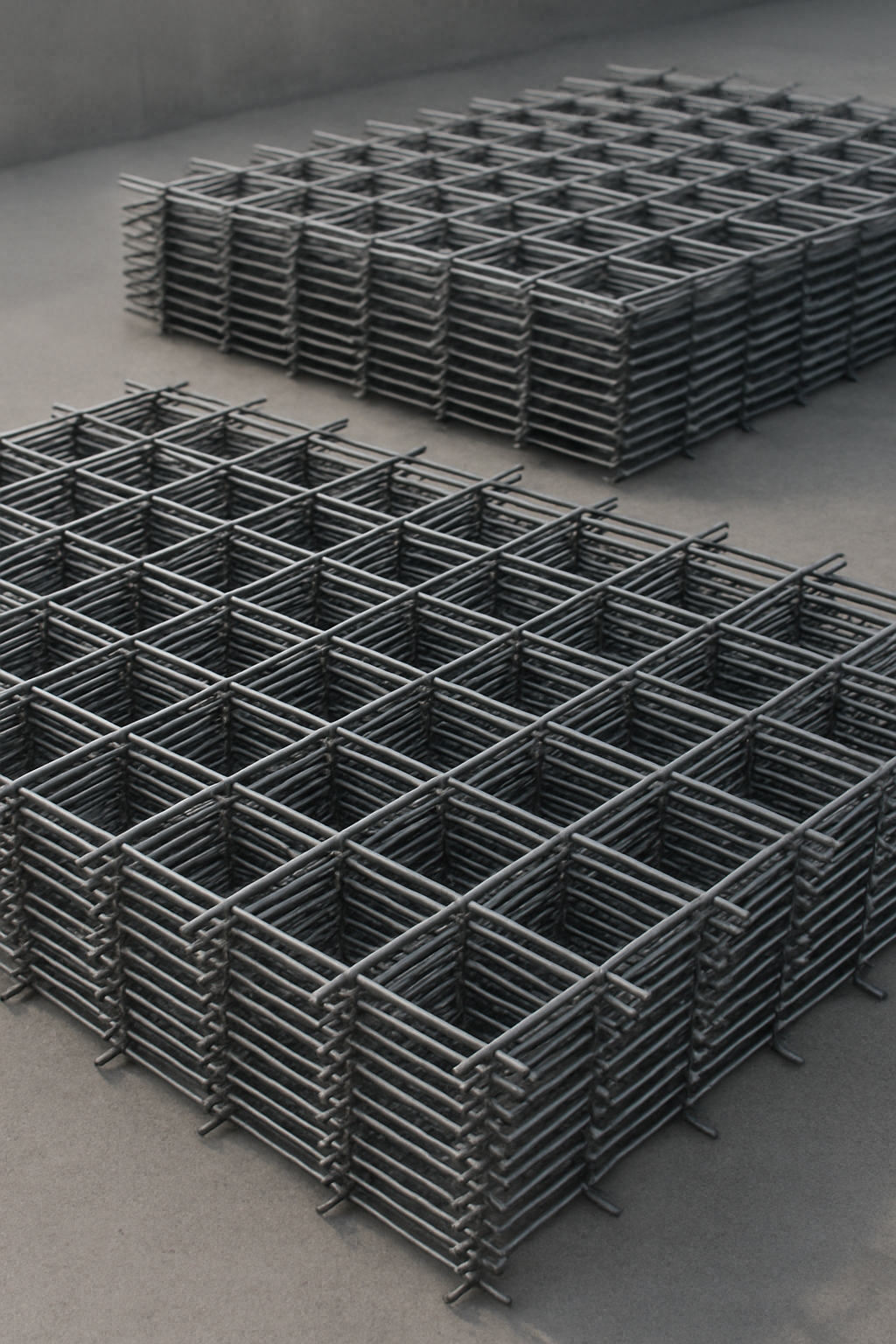

In the evolution of reinforced concrete, Welded Wire Reinforcement (WWR) has transitioned from a secondary "temperature mesh" to a primary structural component. Often misconceived as simple screening material, engineered WWR is a high-tensile, prefabricated steel grid designed to replace traditional loose rebar in a wide spectrum of load-bearing applications.

For civil engineers and project managers, understanding the technical mechanics of WWR is essential for value engineering, optimizing structural efficiency, execution speed, and cost control.

The Manufacturing Physics: Cold-Working and Fusion

High-performance WWR is distinct from standard hot-rolled steel due to its manufacturing process, which alters the crystalline structure of the metal for enhanced performance.

Cold Rolling & Strain Hardening

The process begins with low-carbon steel wire rods. These rods undergo cold rolling, where they are pulled through a series of carbide dies to reduce diameter.

-

Strain Hardening: This "cold working" significantly increases the Yield Strength of the steel. While standard hot-rolled rebar often yields at 420 MPa, cold-drawn wire for WWR typically achieves a yield strength of 500MPa.

-

Profile Deformation: During rolling, the wire is mechanically impressed with ribs or indentations. This geometric profile ensures a high bond coefficient with the concrete, preventing slippage under tensile load and ensuring composite action.

Electric Resistance Welding

Longitudinal and cross wires are fed into automatic welding lines with precise spacing tolerances.

-

The Fusion: High-amperage electric current is passed through the intersection points. The electrical resistance generates intense heat (1400C), fusing the two wires into a homogeneous mass without the addition of filler metal.

-

Shear Strength: This results in a rigid connection where the weld shear strength typically meets international standards (such as ASTM A1064), capable of resisting substantial forces without detachment.

Mechanical Behavior and Structural Advantages

WWR offers distinct mechanical behaviors that are advantageous in concrete design, particularly regarding crack control and load distribution.

Superior Crack Control

Traditional rebar design often utilizes larger diameter bars at wider spacing. WWR allows engineers to distribute the required Steel Area across smaller diameter wires at much closer spacing (e.g., 6mm @ 100mm spacing).

-

Mechanism: Closer wire spacing minimizes the distance between reinforcing elements. This distributes thermal and shrinkage stresses more evenly across the slab, significantly reducing the width of potential cracks compared to widely spaced rebar.

Rigidity and Placement Accuracy

Unlike loose bars which can be displaced by foot traffic or concrete pouring, WWR creates a rigid mat.

-

The fixed welded nodes ensure that the steel remains at the exact design of spacing during the pour.

-

This guarantees that the effective depth of the reinforcement is maintained, which is critical for the flexural capacity of the slab.

Primary Applications

WWR is utilized in sectors ranging from infrastructure to high-rise developments:

-

Slabs on Grade (SOG): Industrial flooring, warehouse pavements, and distribution centers where controlling shrinkage cracks and supporting heavy dynamic loads (forklifts, trucks) is critical.

-

Precast Concrete Elements: Box culverts, tunnel segments, and T-walls. The rigidity of the cage speeds up the casting cycle and reduces the risk of reinforcement displacement during vibration.

-

Structural Decks: Composite metal decks and elevated slabs where WWR acts as the primary tensile reinforcement.

-

Tunneling & Shotcrete: Used as lining reinforcement to provide immediate support and conform to irregular rock surfaces in tunneling operations.

Value Engineering: Material and Labor Optimization

For contractors, the switch to WWR is driven by measurable efficiency gains on site.

-

Installation Velocity: A single sheet of WWR (e.g., 2.4m x 6.0m) covers 14.4m2 and can be placed by two workers in under a minute. Placing the equivalent weight in loose rebar requires tying dozens of individual knots, taking 15-20 minutes. (Impact: Up to 75% reduction in steel fixing time).

-

Tonnage Reduction: Engineered WWR sheets can be designed with variable wire sizes to match the exact moment diagram of a floor slab, rather than using a uniform rebar size that may be over-engineered for certain spans.

-

Lap Splice Optimization: WWR sheets can be manufactured with "flying ends" (overhangs) that allow for engineered nesting. This eliminates the material waste associated with the bulky overlap of traditional rebar.

Compliance Standards

To ensure structural integrity, high-quality WWR is manufactured in strict adherence to global standards:

-

ASTM A1064: Standard Specification for Carbon-Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete.

-

BS 4483: Steel Fabric for the Reinforcement of Concrete.

Sourcing High-Performance Reinforcement

When structural integrity and construction speed are paramount, the quality of the reinforcement material cannot be compromised.

Elsewedy Steel offers premium Welded Wire Reinforcement solutions, engineered to meet the rigorous demands of modern construction. Our facilities utilize state-of-the-art cold-rolling and welding technology to deliver WWR that meets international specifications (ASTM, BS, and ES).

For sales enquiries or further information, click here to contact us. Our team can support product selection, applicable standards, sizing considerations, and logistics coordination for a wide range of prestressed concrete applications. For sales enquiry.